JetVision

Measurement of jet cut-through.

- Continuous measurement of the jet cut-through in real-time and monitoring remotely from the operator station.

- IBS algorithm shows actual jet cut-through length and trend.

- Live- and historical trend information to verify conditions that achieve the best quality.

- Control loop for automatic cut-through control with IBS flexLINE forming boards possible.

- Improved and stabilized strength parameters.

Superior image quality

Our cutting-edge machine vision solutions deliver exceptional image quality, helping you maximize product quality and production efficiency.

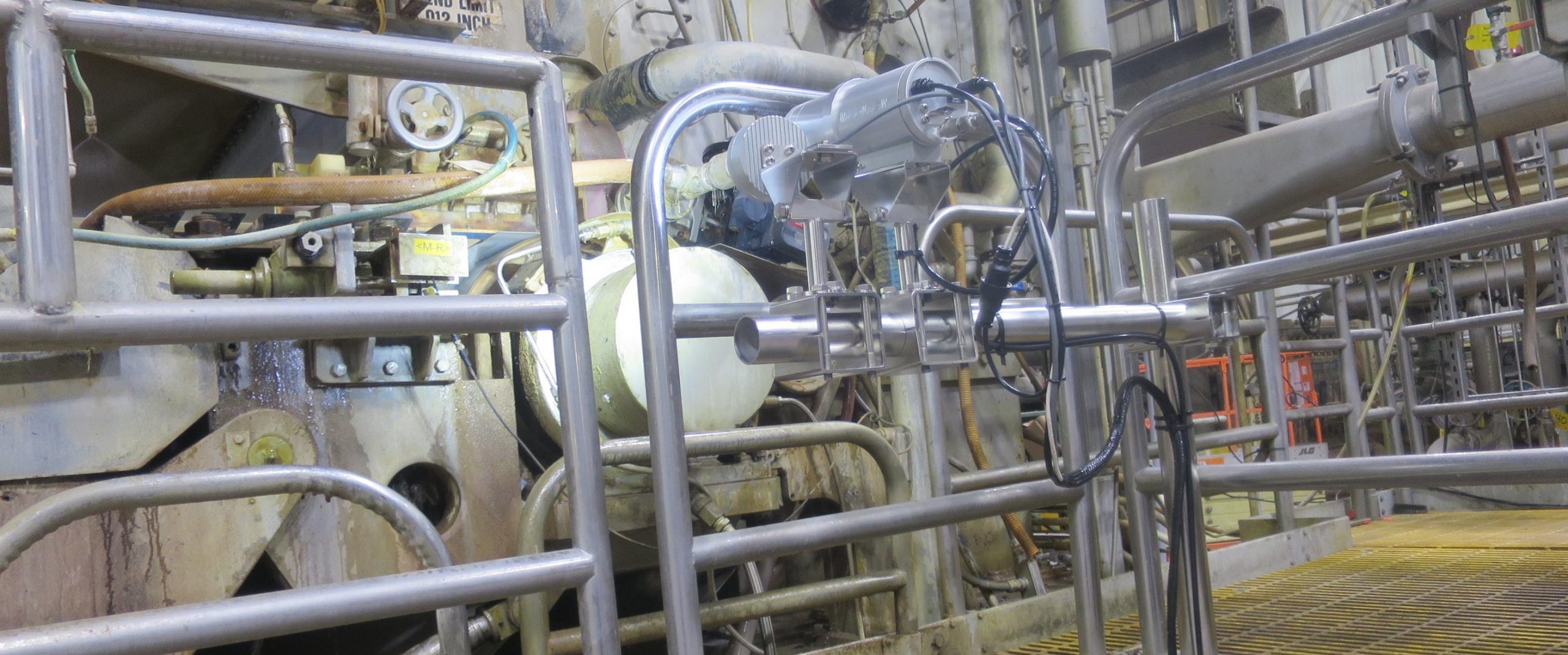

The image shows the jet cut-through recorded with JetVision.

Installation and service

The JetVision jet cut-through camera is mounted on the machine frame at the forming board for easy service access and adjustment.

Installation, maintenance, and repair services on machines monitoring jet cut-through during the paper making process are offered and provided by IBS and Papertech under the JetVision™ mark.

- JetVision camera and lighting are mounted on the machine frame at the forming board